Everyone who is acquainted with KAN-them multisystem knows, that it is a comprehensive offer that allows you to create even the most challenging water and heating installations. To maintain the long-standing operation of our installation systems, we would like to pay your attention to some issues that could shorten the operation period of KAN-therm pipes and fittings and cause unnecessary problems while using.

The focus of this article is aggressive environment that can cause corrosion of pipes and fittings.

Let us start with such KAN-therm systems as ultraLINE, ultraPRESS and Push. What do they have in common? – Pipes made from different types of polyethylene and fittings made from PPSU plastic and brass.

It is worth noting that PPSU is the most corrosion-resistant material. It has practically no interaction with surrounding materials and fluids. But you should always secure such fittings against contact with solvents or solvent-containing materials (paints, aerosols), fitting foams based on methacrylate, isocyanate and acrylate and direct contact with adhesive tapes as they can damage PPSU parts. Keep in mind that connection sealants, cleaners or insulation of KAN-therm system components should not contain compounds that cause stress cracks: ammonia, ammonia retaining compounds, solvents, aromatic or chlorinated hydrocarbons (e.g., ketones and ethers).

A wide range of KAN-therm offer includes metal pipes and fittings too. They are presented in the systems: KAN-therm Steel, KAN-therm Inox and KAN-therm Copper.

Steel pipes and fittings are manufactured out of high quality carbon steel (coated with an anti-corrosive zinc layer) and KAN-therm Inox system elements are made from stainless steel. Despite of the fact that metals are robust and reliable, an aggressive environment can also damage them under unfavorable circumstances.

Though situations in which Steel and Inox installations are exposed to external corrosion are rather rare in indoor installations, do not locate Inox pipes or fittings in humid environment containing or producing chlorine compounds or other halides. Pay attention that corrosive processes are intensified in temperatures above 50 °C. That is why in case of pipe or fitting contact with structural elements (mortar, insulation) producing chlorine compounds, with salt water or other halogens, use water-sealed anticorrosive coating to prevent the material from destruction.

KAN-therm Steel pipes and fittings are externally zinc-plated and have an efficient anticorrosive shield on short-term contact with water. But upon longer contact pipes and fittings must be equipped with tight moisture-proof insulation made of material of closed cells structure (not retaining moisture). It means insulation must be fully waterproof for the entire duration of pipeline to provide proper protection against corrosion.

You can learn more about KAN-therm Inox and Steel systems corrosion protection in The Designer and Constructor Guidebook.

The last but not least KAN-therm system we are going to discuss here is Copper. KAN-therm Copper system fittings made of copper Cu-DHP and bronze 2.109 cannot be used in installations that will be exposed to additional mechanical loads (e.g. hanging on pipelines, devastation, etc.).

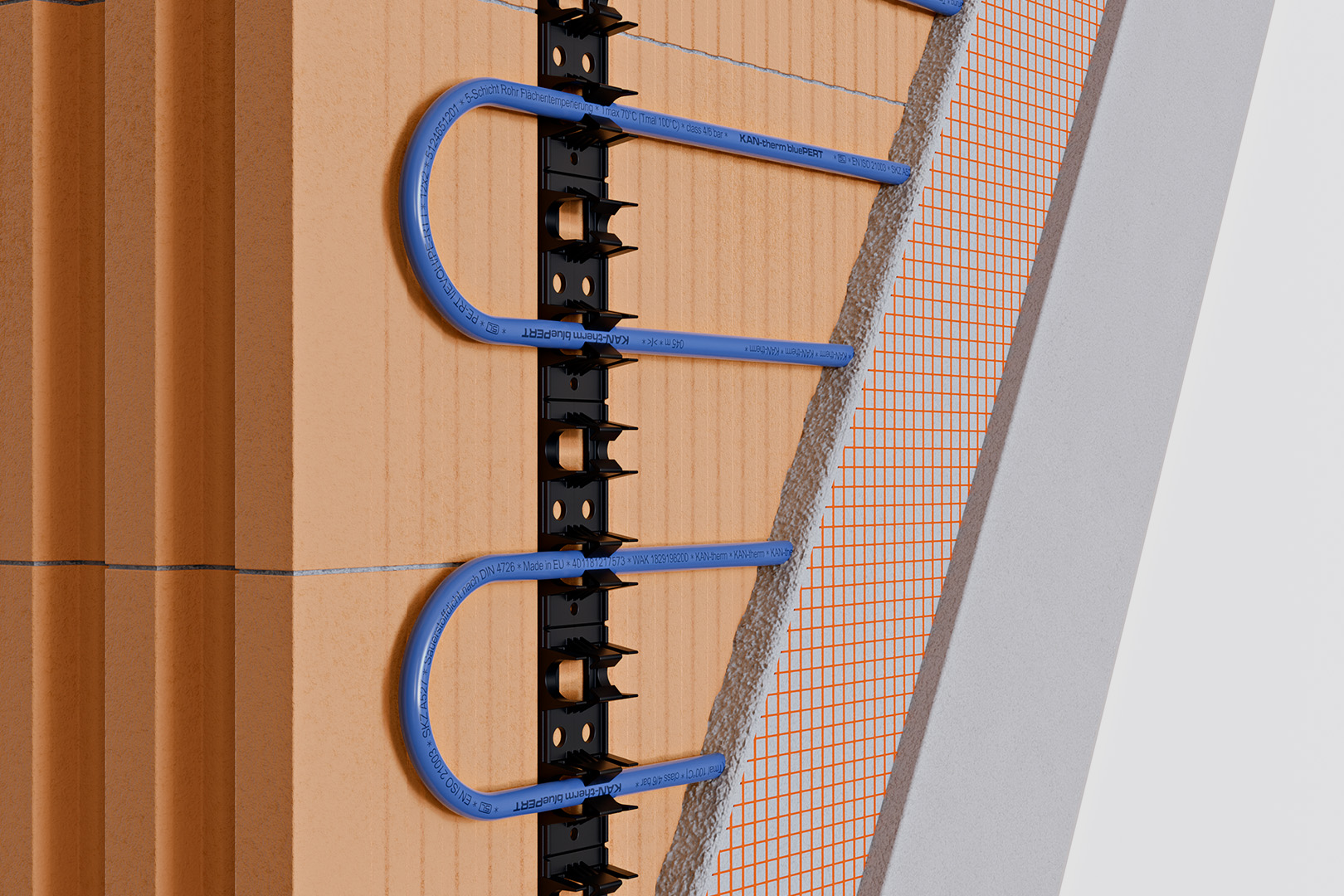

In case of running pipelines inside of building constructions, pipelines should be insulated due to compensate thermal elongations and protection against building chemistry. To avoid external corrosion make sure that the insulation materials do not contain any traces of ammonia or nitrate.

When using external heat sources (e.g. heating cables) to heat the pipe wall, the pipe wall temperature must not exceed 60 °C.

It is also important that installations made in KAN-therm Copper system must be grounded. Pipes intended for water installations that are to be built into partitions (e.g. walls or floors) must always have a shell/sleeve made of suitable material to ensure that the pipe does not come into contact with the building structure due to noise problems.

Putting it in a nutshell, to avoid a negative impact of an aggressive environment on KAN-therm installation systems it is always good to follow the system technical recommendations that you can find in the KAN-therm Designer and Constructor Guidebook or contact KAN-therm Technical Department in untypical cases.